Typical Development Proces

Below is a basic breakdown of our design process. Upon a clear understanding of your project, we develop a step-by-step proposal for you review. We can provide support during a single phase of development, or for the duration of your project. These general stages can vary, dependant on your project needs and/or product type.

Exploration

We conduct preliminary research to better understand the current market, potential competitive products, potential IP opportunities and identify any relevant technologies or materials that may be relevant to your project.

Based on the design brief, we generate a wide range of design concepts using sketches, preliminary 3D CAD and models. From here we identify the best concept, taking in to considerations such as budget, market research and testing feedback.

Development

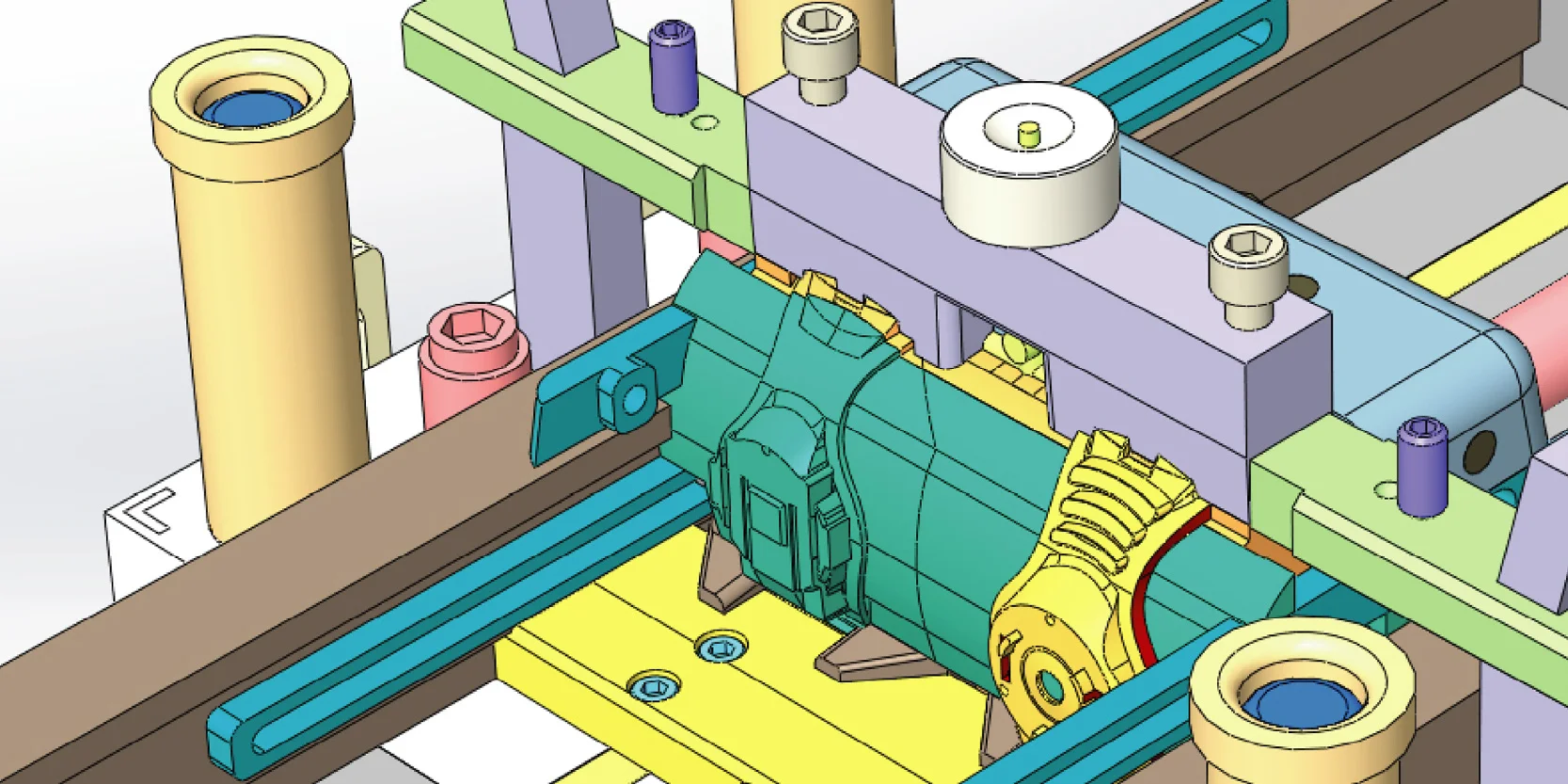

Building on the most promising concept(s), we continue to develop a more detailed embodiment of the select design(s) in 3D CAD, applying appropriate mechanical/electrical engineering, ergonomics, material specification(s), relevant standards or regulatory considerations, cost targets and intended manufacturing methods etc.

Further prototyping is often critical at this stage, allowing us to test, evaluate and validate the design intent through mechanical testing and user and market feedback. This stage also allows us a clearer understanding of likely production costs, to seek possible IP, ensure relevant certifications can be met and help build a clearer business model.

Branding, product information and packaging considerations would also be incorporated into this stage of development.

Refinement

Design refinement is typically where much of the final efforts into design and engineering detailing, product performance and manufacturing specifications are met (often led by the results of the previous phase prototyping and testing). Final prototypes are again encouraged for validation testing prior to production commitment.

This refinement stage also allows for accurate costings with manufacturing specifications confirmed and any standards or regulatory requirements validated/approved. All branding and packaging documentation would also be completed.

Finalisation

Upon completion of validation testing, all design, material and manufacturing documentation would be completed and reviewed with intended manufacturer. Quality Control Procedures would also be addressed and production expectations and timelines confirmed.

Manufacturing Support

We can recommend manufacturers and suppliers, or work with your preferred vendors. We can then liaise with the manufacturers through first samples, and support any required modification to ensure the quality of your product.

Got a question?

Each product will have a slightly different path to manufacture, talk to us today about how we can help with your product specifically.